3D Printer Bootcamp v1 Wrap-up

We sat down with Dr. Chad Wingrave and interviewed him on his experience of facilitating our first build-your-own 3d printer boot camp. Here’s what he had to say:

Sign up for Boot Camps v2 or v3 (Aug 1 & Aug 29)

Q: Who showed up to v1?

“Five groups of makers showed up today and walked out with five new 3D printers. There were techies and father-son teams, even someone that wanted to do the build with one arm (they have two arms, but had a broken collarbone). Needless to say, we had a blast: built a lot, learned a lot and even had some pizza.”

— Dr. Chad, Chief Tinkerer

Q: What was the rollout like?

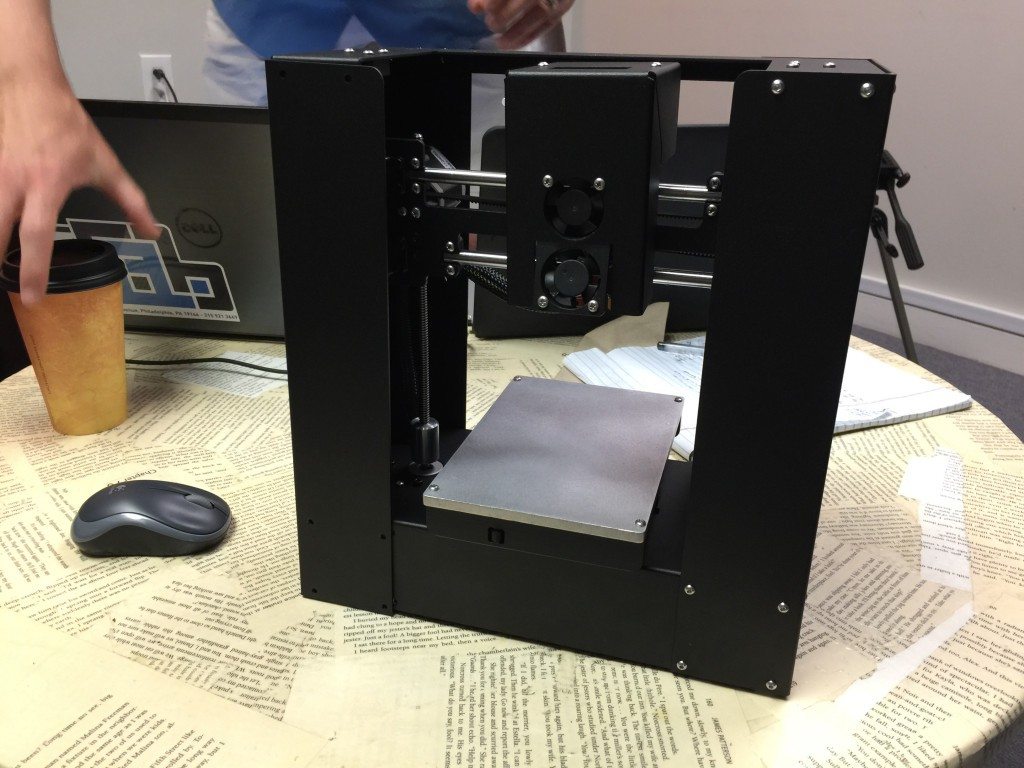

“The bootcamp started with a box of parts from PrintrBot and a goodie bag from Printed Solid. The PrintrBot Play was chosen for its quality parts and semi-ease to assemble. While it has a small build area, it is a solid 3D printer that should be able to support a budding 3D printer.”

“We got started with a quick overview of the day and introductions. We talked about why each person wanted to have a 3D printer an let them know about our plans for developing a community of innovative makers in Walnut St Labs. Then, we started to build. We had great support from two interns, Peter Terjanian and Andrew Telepak. Their efforts putting together a printer for Walnut St Labs enabled them help our makers avoid those ‘gotcha!’ moments that waste time and cause confusion.”

— Dr. Chad, Chief Tinkerer

Q: What did they learn about 3d printing?

“At lunch, we paused for a quick bite to eat and some instruction about 3D printing and how to use the printers. It was quick and we dovetailed back in to the build process. The topics covered included workflow, types of 3D printing, materials and other vital concepts. Its important to mention that all the participants for this bootcamp and future bootcamps will be onboarded to opensource software. The opensource component is central to our access-based mission. We’re excited that the opensource community is growing in so many different directions.”

— Dr. Chad, Chief Tinkerer

Q: So, how did we do?

At the end, we had a great photo op with the new printers and the smiling faces. While some had more time to configure and play with their printer, all walked out with full assembled printer (except for the group with one arm that had to finish up at home). Additionally, all joined our new Makerspace community hub and plugged in to the continuing activities here at the labs.”

— Dr. Chad, Chief Tinkerer

Q: What’s next for the MiniMakerSpace at WSL?

“To support our group, we are rolling out Wednesday meetups, which co-exist with our Night Owls event and are planning two more Bootcamps, this time on Saturdays (August 1st and August 29th). We hope you are able to join in at these events! We also plan to expand on workflow (the process of creating 3D models capable of being printed on a 3D printer) in upcoming iSchool Classes out of Walnut St Labs focusing on the available open source software.”

— Dr. Chad, Chief Tinkerer